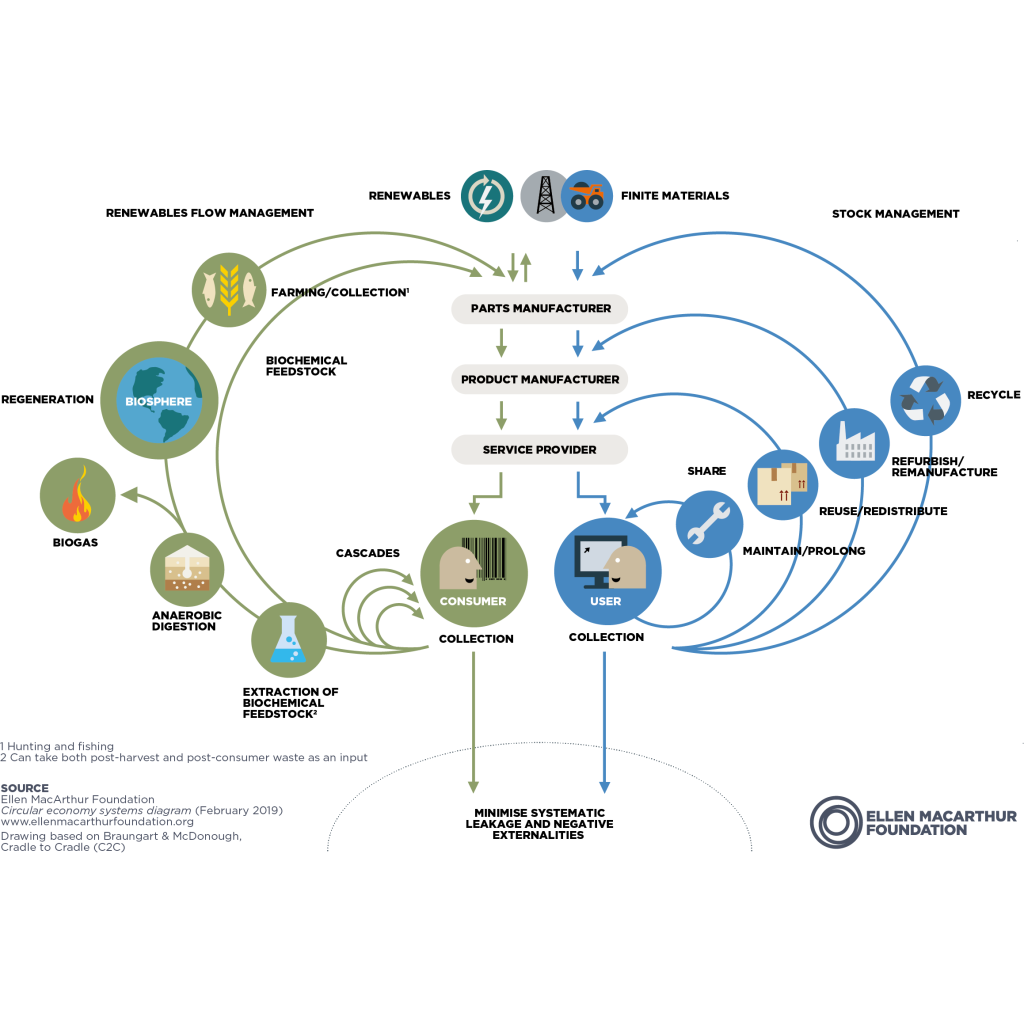

Textile industry has been dealing with issues around sustainability for many years. Scientists have been calling for to act and move out from fast fashion that it won’t be possible for nature to withstand concept of manufacture, use and dispose. Preferable is to keep value of those products and resources as long as possible in the loop. There are two main cycles in continuous material flows – the technical cycle and the biological cycle. In the technical cycle, the products regeneration processes are driving force such as reUse, rePair, reManufacture, reDesign and reCycle. Contrary, in the biological cycle, the nutrients from materials which biodegrade are returned to the Earth to regenerate nature. Those two cycles are also given in below Butterfly Diagram sourced from Ellen Macarthur Foundation.

“Fashion with reduced climate impact and thinking about next generations has to be more about hunting for new innovative possibilities and redesigning the future of fashion than mitigating negative impacts.”

Brief summary in short video can be found here.

Recent years we see the growing pressure from consumers to make the products which are more sustainable. They became a driving force for brands that they held to take care more about the nature and next generation to create products which contribute less or very little to pollution. There is also pressure from government regulatory bodies in particular initiative by European commissions, European Green Deal and circular economy action plan this is introduce regulatory laws to force the fashion industry to adopt the circular economy principles if you have particularly affected fast fashion and others waste and pollution within the textile industry it’s long-term objective is to shift the textile industry to produce longer lasting reusable and recyclable product.

“Through centuries of evolution the nature has developed a brilliant high-tech fibre with unique characteristics that make it an ideal fibre to fit into the principles that encompasses the biological circular economy model better than any other fibres used in textiles today.”

Above picture represents the reGenerative creation of products using raw wool fibre and the flow of wasted wool for biofabrication.

Above picture represents the reGenerative creation of products using raw wool fibre and the flow of wasted wool for biofabrication.

Wool is Natural. It grows as the side product of soil, sun, rain and grass.

Wool is Renewable. Sheep produce new fleece every year. The animals are typically sheared once a year. This helps them be more comfortable during the warmer months. Sheep then regrow their coat over the course of the next few months to be ready in time for the cooler weather.

Wool creates biodegradable microfibers. Yes, microfibres, but unlike synthetics they are biodegradable.

Wool is Biodegradable. Like a human hair and being therefore natural fertiliser. It decomposes in soil within only a year, and at the same time it gradually releases the natural fertilising nitrogen nutrients back into the ground. By contrast, synthetic fibres can take many decades to decay, potentially polluting and damaging the environment. See also previous blog.

Wool is local. European. Austrian. German. Swiss. Vorarlberg. Montafon. Tirol. Application needs to consider based on the qualities as mentioned earlier.

Wool is circular, earth-friendly natural product which fits to circular economy action plan to produce longer lasting reusable and recyclable product.

Wool is of high-quality material which last longer.

Wool is easy to care for. Oft is enough to air dry wool product overnight, and next day is ready to wear.

Wool is Mulesing-free. Mulesing is a painful surgical procedure to prevent sheep from being killed by infections caused by insects –blowflies.

Sheep have cloven hooves which help to promote healthy grass roots and are regularly used on mixed farms to complement the growth of other crops as they promote significantly improved soil health and fertility.

Wool is resource of employing regenerative agriculture practices and well-disposed to waste and pollution control. For many regenerative agriculture is a question of simply doing back to pre-industrialized or agroecological farming practices where monocrops, synthetic fertilizers and overgrazing simply are a “no go”. Or she and Boo these my mean system of moving livestock to follow the seasonal changes in grazing areas or other ways of moving them around. They are already many examples of projects which demonstrate the manufacture beneficial impact that integrated livestock system can play on the farms and rhyme cheese. It is now that sheep play a key role in their operations improving soil health and fertility through nutrient cycling reducing meat pressure and fire hazards and reducing the hormone of human labor needed to defoliate the craves graves among many others benefit” says Rebecca Burgess, founder of Fibershed.

Wool fits greatly into a sustainable circular model of textile production that minimizes waste and pollution. It is one of the most suitable fibers that can help to create more earth friendly products on infection in listening.

Apart of placing wool (waste or used) in soil to help grow threes, it has a great potential to “open doors” of biofabrication. Bringing together computational design, material engineering to synthetise new nano-fibres, bioplastics, bio-based textile finishing or materials for additive manufacturing will bring a new value of the material which is around for centuries, and currently rather wasted.

European Wool is still treated as waste product although annual shearing (necessary for well-being of animals) brings over 300 000 tonnes of this great nature product. The quality varies, but this brings also the versatility of wool use. The most spread use is for isolation in all different sectors including apparel industry. For instance, the total keratin waste (wool, feather, hoofs, horns etc.) is estimated at 5 million tons annually.