As a result of solar energy, soil, water and CO2, the earth is a large reservoir of plant and animal resources.

Cellulose is being most likely old as the creation of plans. It is difficult to verify when cellulosic materials were used the first time for clothing because of the biodegradability, but the oldest cotton textiles found go back 5,800 BC and were found in a cave in Tehuacan in ancient Mexico. Other important sources like flax, linen, hemp or wool were also used in early history.

Cellulose as a renewable plant-based material, is the most abundant biopolymer on earth and of particular interest in providing renewable and biodegradable biopolymer for industrial applications. It can be acquired from a wide range of resources: microorganisms like bacteria, cellulose plants like cotton, flax, hemp, ramie, jute as well as those derived from eucalyptus, pine or wood pulps for fibres such Viscose, Modal, Tencel, EcoVero or Naia.

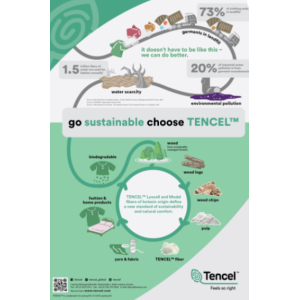

Infographic: the production process of TENCEL™ Lyocell and TENCEL™ Modal fibers. Source: Lenzing AG

Regenerated cellulosic fibers or man-made cellulosics are usually manufactured from purified wood pulp, mainly produced from sustainably grown wood using a unique closed loop system and linters but also from annual plants like eucaliptus. Advantage of this raw material is that grows rapidly and requires very little water, pesticides and fertilizers. To convert this wood pulp into textile fiber, first it is liquefied in a suitable form from which it can be manufactured as continuous very tiny fibre. The performance of those fibres in wear is in their extremely soft (silky) touch, lustre, certain cooling effect and fibre strength when wet.

At present there are three processes which are mostly used:

- viscose

- lyocell, and

- cuprammonium process.

The outcome of these three processes are viscose fiber, modal fiber, lyocell or tencel fiber and rayon. Tencel is an Austrian innovative fibre. Most recent development is Naia fibre which is an cellulose acetate with recovering solvents/chemistry involved in the process.

The main difference among these fibers comes from the ecological and environmental impact in regard to chemistry used in the processes, water consumption associated with the process, and the fiber structure and morphology. Considering water consumption EcoVero fibre lowers water impact up to 50% in comparison to generic viscose which is 12,5 L and more. As stated here cotton processing needs 210 L and more water. What is important for manufacturing of cellulosic fibers is the close loop processes allowing recovery and reuse of chemicals and water used for manufacturing the fiber. In accordance with report of Textile Exchange, a global nonprofit that drives for urgent climate action on textile fibre and materials, in material changing inside 2020, the highest rated forestry risks is deforestation.

Recently seen TED talk of Dan Hammer was kind of eye opener. He helped to work on an open platform to identify the forest station almost in the real time using a satellite imagery and calls Global Forest Watch. It helps to provide more details about the forest station which moves across the landscape pixel by pixel occurring also through Amazon. Actually when one looks on the pictures provided on the platform it looks quite scary. There are already many of projects searching loads of data and monitoring snow fish or water changes. All of them are important and what they have in common is to better understand what’s going on in the world and why it is happening – you can’t change what you can’t see.

Another risks lies in logging of high conservation value forests, biodiversity loss and land use change, climate change, indigenous communities and labour related risks. Unfortunately, from the same report it can be seen that the 60% of man-made cellulosic supply is unknown. Another currently rising point is the lack of wood and wooden resources.

Anyway, lyocell processes have a great potential in future to be used, mainly those which are capable to recover the solvents used in course of manufacturing, use non-toxic solvents producing non-hazardous effluent. For example, Lyocel fibre or better known Tencel is recovering >99% of the solvent which is non-toxic.

Although, the process is fairly sustainable, the critical point could be sourcing the raw material. As mentioned above the fibers are manufactured from the wood pulp and hence, wood and pulp has to be only from certified sustainable sources.

Why wood and pulp has to be carefully sourced to make fibre?

Because, in hunting for green or naturally-based fibres to use in clothing, in a long journey to become a fibre, some threes from rainforest could land as what we wear. A documentary on the topic could be found here. For instance, Lenzing AG, one of the biggest manufacturer of wood-based fibers, goes transparent by providing the list of the pulp sources. At this point, certification helps ensure compliance and builds trust in products. In this regard there are two standards, both help to protect ancient, engaged forest and ensures no deforestation of protected forests happens.

The Forest Stewardship Council (FCS) – non-governmental organisation dedicated to promoting responsible management of the world’s forests, forest certification and product labelling that enables people to identify responsibly sourced wood, paper and other forest products. The Programme for the Endorsement of Forest Certification (PEFC) provides independent verified assurance that the certified forest-based material contained in a product originates from sustainably managed forests.

Another option is Conopy which helps to develop policies by working with biggest customers and their suppliers to develop business solutions that eliminates sourcing from Ancient and Endangered Forests and brings game-changing solutions from the margins to the mainstream.

Other innovative processes use different source of cellulose. Cellulose extracted from waste of agricultural plantations or from industrial processing of fruits used in juice industries like citrus-based fibers or from textile waste, and other fruit resources like oranges, pineapple, banana or apples.

Why forests are important?

Forests play a critical role for the global environment, population and economy. Besides helping to reduce the effects of climate change including natural disasters, they represent some of the richest biological areas on Earth. They also provide food, renewable raw materials for many of our products, and livelihoods for millions of people.