ALPBOCK

Our Factories

“We don’t just choose factories.

We choose people, values, and responsibility.”

The factories

Every ALPBOCK product has a story and it starts long before you hold it in your hands.

It starts in small European factories where craftsmanship is still a daily practice, not a marketing term.

We work closely with people who care deeply about what they make. Family-run businesses, skilled teams, and partners who have spent decades perfecting their craft. Places where materials are understood, machines are respected, and quality is never rushed.

We believe great products come from trust and long-term relationships. That’s why we visit our factories, know the people by name, and develop pieces together patiently, thoughtfully, and with purpose. Step by step. Stitch by stitch.

By producing close to home and keeping supply chains short, we protect quality, reduce impact, and create products meant to be worn, lived in, and loved for years.

This is our way of making things.

This is where ALPBOCK is made.

Yarn Manufacturing Partner (Garments), germany

Before fabric is knitted and garments are shaped, everything begins with yarn.

For our apparel pieces, we work within a trusted European yarn ecosystem, starting with a family-owned yarn spinning partner headquartered in Germany, whose expertise lies in fine merino wool.

This partner transforms carefully selected wool fibers into high-performance yarns that define how our garments will feel, move, and last. Decisions made at this stage such as fiber selection, spinning method, yarn structure determine breathability, softness, durability, and long-term comfort long before the first pattern is cut.

These merino yarns are used directly by our textile manufacturing partner in the development of our fabrics. This close collaboration between yarn spinning and fabric knitting creates a true Fiber to Fabric flow, ensuring that material quality remains consistent and intentional throughout the entire process.

For us, yarn is not an invisible component, it is the foundation. By keeping this step within a transparent, European, and family driven supply chain, we ensure that our garments start with integrity and end with purpose.

This is how our DNA comes to life: from fiber, to yarn, to fabric, to garment without shortcuts.

Key facts:

Founded: 1966

Ownership: Family-owned yarn-spinning company

Headquarters: Germany

Products: Merino T-shirts, headwear, neckwear

“We design garments by thinking from the fiber forward and not from the trend backward.”

Textile Manufacturing & Confection Partner, Czechia and Slovakia

Our performance merino fabrics are developed together with a trusted Czech textile manufacturer rooted in decades of European knitwear heritage. Built on precision, material knowledge, and responsibility, the company represents a long-standing tradition of textile craftsmanship that continues to evolve through modern development and testing.

What began as a traditional knitting facility has grown into a close development partnership. Today, traditional know-how is combined with modern knitting technology, in-house testing, and short decision paths — allowing consistent quality, functional performance, and durability across every fabric.

A defining part of this collaboration is co-creation. Together, we develop and refine our T-shirts, beanies, neckwear (tubes), and headbands, working side by side on fit, fabric feel, performance, and finishing details. Each piece is tested, adjusted, and improved with the goal of creating garments that feel natural on the body and perform in motion.

Once fabrics are finalized, garment confection takes place in a specialized production facility in Slovakia, ensuring high-quality assembly, careful finishing, and consistent standards across every piece. Produced locally in Europe in limited runs, these textiles and garments form the foundation of products made to be worn often and kept for a long time.

This partnership reflects what we believe in: co-creation over outsourcing, craftsmanship rooted in heritage, and materials developed with purpose.

Key facts:

Focus: Textile & garment development (knit fabrics and apparel)

Products developed together: T-shirts, headwear, neckwear

Fabric development: Czech Republic

Garment confection: Slovakia

Employees: 50 – 99

Last visit: Summer 2024

“From fabric to finished garment — developed together, made to last.”

Dyeing & Finishing Partner, Poland

Colour is more than appearance, it’s the final expression of a fabric’s character.

Our textiles are dyed and finished in collaboration with a long-established European dyeing and finishing house, where experience, precision, and responsibility come together.

For decades, this partner has worked at the intersection of textile craft and modern technology, transforming raw fabrics into finished materials that are ready to be worn, touched, and lived in. Every step is carefully controlled — from colour consistency and fabric stability to surface feel and long-term durability.

What truly sets this partner apart is their deep commitment to environmentally conscious production. Through advanced eco-dyeing and finishing technologies, water and energy consumption are significantly reduced, chemicals are precisely managed through automated systems, and wastewater is treated and reused in closed loops. Sustainability here is not a statement it is part of everyday practice.

Working hand in hand with upstream partners, dyeing and finishing are closely aligned with fabric construction and yarn selection. This ensures that colours and finishes support performance rather than compromise it, allowing garments to age gracefully, feel natural on the skin, and remain comfortable over time.

This partnership completes our Fiber to Fabric to Garment approach where colour, function, and responsibility belong to the same process, not added at the end.

Key facts:

Founded: 1991

Ownership: Family-owned company

Employees: Approx. 280

Focus: Textile dyeing & finishing

Sustainability: Eco-dyeing technologies, reduced water & energy use, closed-loop wastewater treatment

Role in supply chain: Colour & finishing step within Fiber → Fabric → Garment

“Where colour meets responsibility and materials are finished with care.”

Knitwear Manufacturing Partner,

Our Woolen Heritage, Austria

For decades, this partner has worked at the intersection of textile craft and modern technology, transforming raw fabrics into finished materials that are ready to be worn, touched, and lived in. Every step is carefully controlled — from colour consistency and fabric stability to surface feel and long-term durability.

We collaborate with a European knit- and felt-work partner based in the Alpine region — a producer whose soul belongs to wool, tradition and the natural world. Their motto says it all: “From nature, with nature.”

In their workshop, wool is transformed by hands and hot water, never by harsh chemicals. Fabrics are knitted or felted into cosy, robust products, pieces meant to be lived in, loved, and worn through many seasons.

This partner respects the slow pace and authenticity of natural-fibre craftsmanship. By choosing 100 % natural wool and relying on traditional, chemical-free felting and knitting techniques, they help us stay true to our belief: garments should be honest, pure, and responsibly made.

With them, we don’t just produce clothes, we revive a legacy of wool-work rooted in respect for material, nature and time. Each knitted or felted piece becomes a story: of heritage, of sustainable making, and of comfort that comes from nature itself.

Key Facts:

Focus: Knitted & felted wool garments and accessories

Materials: 100 % natural wool, chemical-free felting

Employees: about 10

Production style: Craft-based, small-batch manufacturing

Last visit: Summer 2024

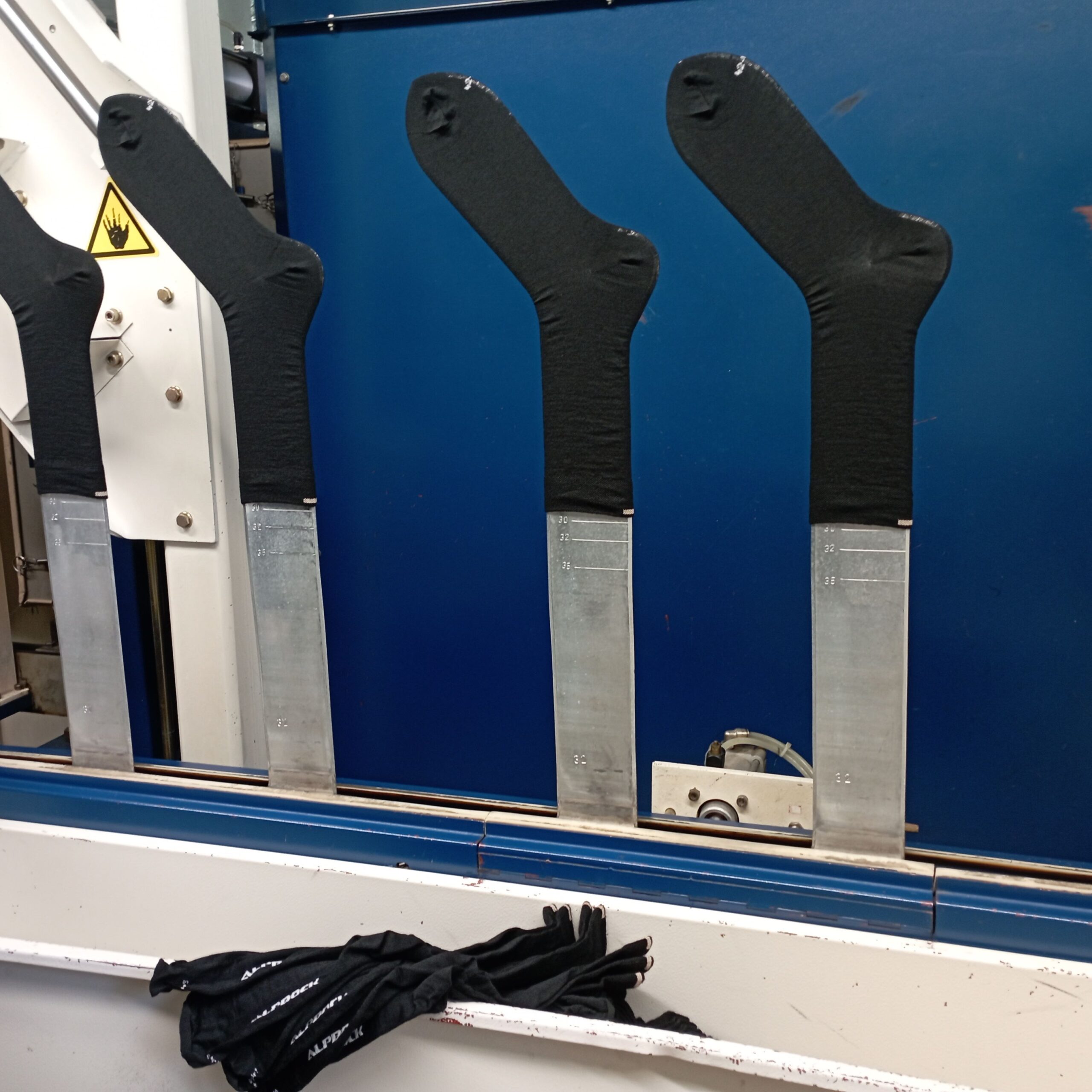

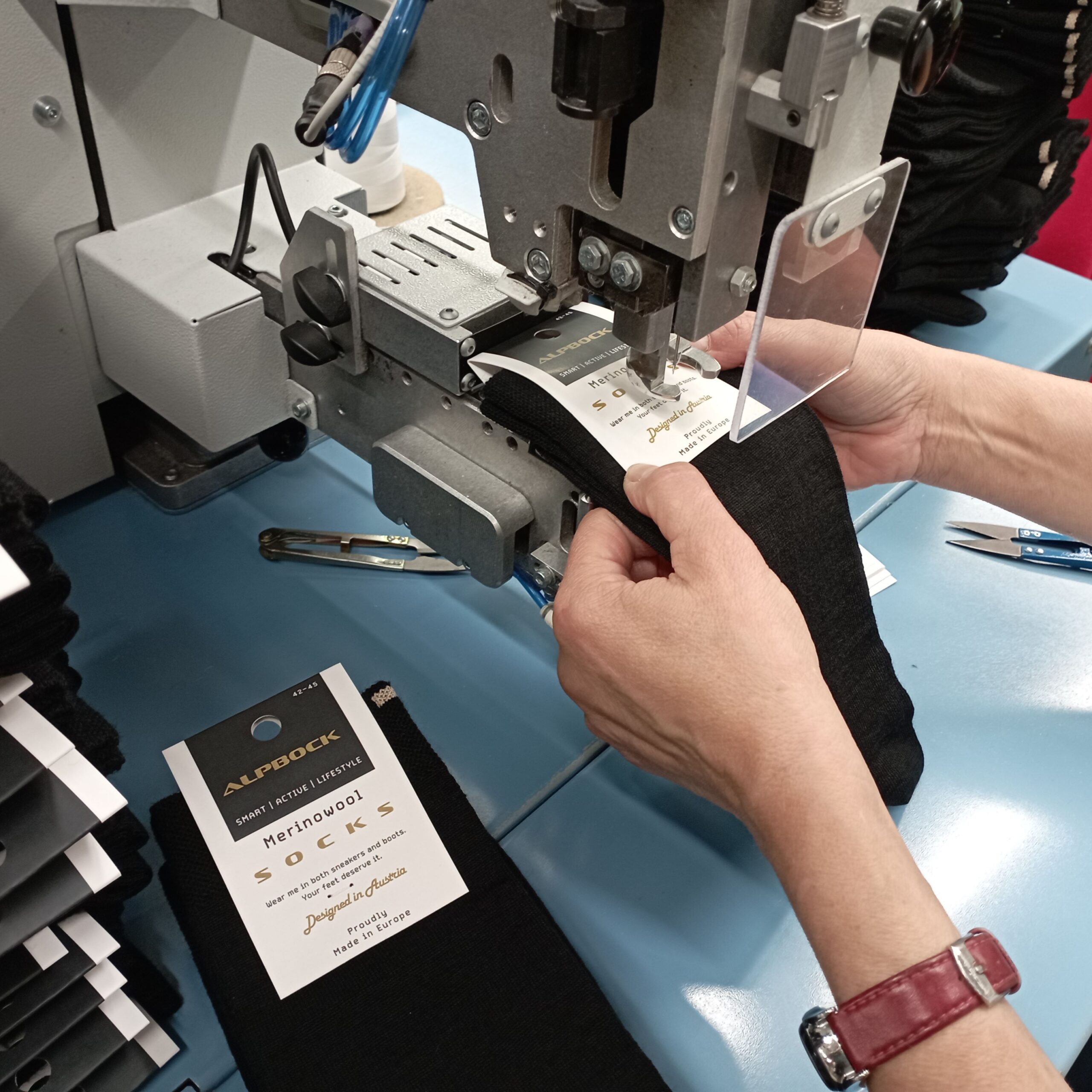

Socks Manufacturing Partner, CZechia

Our merino and design socks are produced by a traditional Czech sock manufacturer with roots going back to 1935, when Tomáš Baťa introduced sock production and laid the foundation for one of the country’s longest-standing hosiery traditions. This early start shaped decades of expertise in fine hosiery and functional sock manufacturing.

Today, the family-run company operates with a small, highly skilled team and a strong focus on quality, durability, and craftsmanship. Many employees have grown with the company over the years, contributing deep practical knowledge and consistency to every production run.

The manufacturer works closely with a local yarn supplier located just around the corner, enabling short transport routes, fast coordination, and stable yarn quality. In addition, high-quality yarns are used for selected products to meet demanding performance and comfort standards.

All socks are knitted locally in Europe in limited runs, allowing precise control over materials, fit, and finishing. This partnership makes it possible for us to develop both performance merino socks and custom-designed socks with regional stories and thoughtful design details.

Key facts:

Founded: 1935 (sock production introduced by Tomáš Baťa)

Employees: 20

Working hours: 8 hours / 2 shifts

Products: Merino socks & custom-designed socks

Last visit: Summer 2021

Rooted in tradition and shaped by modern design, this manufacturing partner stands for European craftsmanship, short supply chains, and long-lasting quality.

Knitwear Manufacturing Partner, Lithuania

Knitting is where structure becomes comfort and yarn turns into something you can truly feel.

Our knitted pieces are created in collaboration with a specialized European knitwear partner whose craft lies in shaping yarn into garments made to move, breathe, and last.

This partner brings together modern flat-knitting technology and decades of hands-on experience. Every stitch is placed with intention, balancing elasticity, softness, and durability to create knitwear that feels natural on the body and reliable in everyday use.

What defines this collaboration is respect: for materials, for people, and for the process. Production is carefully managed, from yarn handling and knitting to finishing and quality control, ensuring consistency across each piece while allowing flexibility for thoughtful design details.

Sustainability is part of the mindset. By investing in efficient machinery, renewable energy sources, and responsible production practices, this partner reduces environmental impact while maintaining high standards of craftsmanship and working conditions.

Working closely with our upstream partners, knitting is aligned with yarn selection and fabric development — reinforcing our Fiber to Fabric to Garment approach. The result is knitwear that feels considered, wears beautifully, and is made to be part of your life for a long time.

Key facts:

Location: Lithuania

Employees: Approx. 200

Specialisation: Knitwear production (flat knitting)

Machinery: Modern flat-knitting machines (fine to medium gauges)

Production capacity: Small to medium runs

Sustainability: Renewable energy use, efficient machinery, responsible production practices

Role in supply chain: Knitwear manufacturing within Fiber → Fabric → Garment

“Shaping yarn into knitwear made for movement, comfort, and long life.”

Loden Manufacturing Partner, Austria

There are few materials in the world that speak as deeply to landscape, climate and craft as Loden — and our partner in producing this remarkable cloth embodies that legacy. At the foot of the Alps, a tradition of wool working has been carried forward since 1888, when the original Loden manufactory was founded to create cloth that could withstand mountain winds and weather.

Here, fabric is not made — it is grown through time. Wool is transformed through dozens of careful steps, most still rooted in handwork, into a compact, breathable, weather-resistant cloth that warms, protects, and evolves with use.

This partner’s journey is one of enduring craftsmanship: from a handful of dedicated makers to a respected European producer that still lives by values first set over a century ago — authenticity, material respect, quiet innovation, and transparent quality that you can feel in every touch.

Our collaboration with them is more than sourcing fabric — it’s embracing a worldview where natural materials are celebrated, heritage is honored, and products carry a sense of place and purpose far beyond their stitches.

Key Facts

Founded: 1888

Heritage: Continuously producing traditional wool fabrics for well over a century

Products: Loden cloth

Craft: 40+ traditional production steps in the wool process — from fibre to full-bodied cloth

Visit: Summer 2024